Introducing the APM 2500 Thermoforming Vacuum Packaging Machine

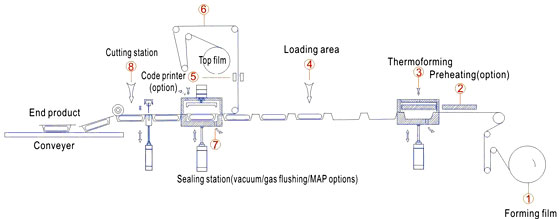

Discover the APM 2500, an advanced thermoforming vacuum packaging machine meticulously designed for packaging food, non-food, or medical products. This innovative machine directly creates packages using bottom and top rolls of film stock. Tailored for small-scale business operations, the APM 2500 series excels in packing meat, fish, cheese, seafood, dairy products, pharmaceuticals, and more. With versatile options such as vacuum, gas flushing, and MAP, the APM 2500 series emerges as your go-to roll stock thermoformer, ensuring flexibility and efficiency in packaging solutions.

- Capacity max.10 cycles.

- Bottom film: Rigid or Flexible

- Top film: Flexible (PA/PE film, paper, aluminium foil)

- Loading area max.800mm.

- Width max.420mm.

- Forming depth max.100mm.

|

|||

Compared to the manual vacuum packaging are:

- Reduced package cost up to 50%

- Increased productivity

- Improved product appearance

- Less product handling in the packaging process

- Prevent product contamination

- Greater assurance of packaging

Construction features:

- Solid stainless steel frame, for strengthening of systems and mechanisms and for safe transportation.

- Machine is constructed of stainless steel AISI 304

- Durable gripper chain guides casing.

- Corrosion-resistant gripper chain.

- All Scandivac machines are equipped with servo drive system for gripper chain.

- 4 or 6 point independent lifting mechanisms with pneumatic drive and grease lubrication from a central location.

- Freely variable distance between moulds, giving a possibility to use dies with different cut-off lengths.

- Easy access to any system or mechanism, with easy open side guards.

- Components with protection level – IP 65 as standard.

Control system:

- Control panel: Color touch screen panel.

- Control elements: Allen Bradley or OMRON programmable controller.

Vacuum system:

- BUSCH vacuum pump;

- IWN vacuum valves.

Product:

Using thermoforming vacuum packaging machine SCANDIVAC it is possible to pack any product in industrial, food and medical sectors. It is possible to pack large amount of products in the shortest possible time. Design of the package is tailor-made.

Film specification:

- Film width: from 320 up to 600 mm;

- Upper film: flexible film, paper, folio. Thickness up to 100 microns;

- Lower film: rigid film, flexible film, folio. Thickness up to 1000 microns;

- Printed upper film.

Cut off length:

- Without pre-heating: up to 800 mm;

- With pre-heating: up to 600 mm.

Type of the packaging:

- Only sealing;

- Vacuum and sealing;

- Vacuum and gas and sealing;

- Skin packaging.

Packages:

- Hanging hole – round O;

- Hanging hole – euroslot

Types of cutting:

- Cutting shape

- Longitudinal perforation;

- Cross-cutting perforation.

Types of forming:

- Only with compressed air;

- With compressed air and vacuum;

- Plugs: unheated / heated;

- Posiforming.

Longitudinal cutting:

- Rotary knife assembly;

- Squeezing knife assembly;

- Roller shear cutting assembly – line cutting;

- Roller shear cutting assembly – strip cutting.

Cross cutting:

- Cross cutting unit for flexible film – straight cut;

- Cross cutting unit for flexible film – zig-zag cut;

- Cross cutting unit for rigid film with round corners.

Options:

- Labeling machine;

- Water cooling system;

- Printer;

- Dosing system.

TECHNICAL DATA

Model

Specification |

APM 2500 |

||

| Film width (mm) | 320 and 420 | up to 600 | up to 600 |

| Upper film material | Flexible film, paper, folio | ||

| Lower film material | Rigid film, flexible film, folio | ||

| Upper film thickness (microns) | up to 100 | up to 100 | up to 100 |

| Lower film thickness (microns) | up to 400 | up to 1000 | up to 1000 |

| Cut-off length without pre-heating (mm) | 200, 240, 270, 300 | up 600 | up to 800 |

| Cut-off length with pre-heating (mm) | 100, 110, 120, 130 | up 400 | up to 600 |

| Reel max. diameter (mm) | 400 | 400, jumbo 1000 | 500, jumbo 1000 |

| Max. forming depth (mm) | up to 100 | up to 130 | up to 200 |

| Loading area max. (mm) | up 800 | up 2500 | up 3500 |

| Max. capacity (cycles/min) | up to 10 | up to 15 | up to 15 |

| Conveyor motor | Servomotor 1 – 2 kW | ||

| Vacuum pump (m3/h) | 40 – 100 | up to 400 | up to 400 |

| Needed capacity (kW) | 4 – 6 | 4 – 8 | 6 – 12 |

| Compressed air (bar) | 6 | ||

| Cooling system (L/h) | 70-120 | 100-150 | 150-200 |

| Control system | «Allen-Bradley» programming control system + colourful LCD touch screen (TFT, Touch Screen) | ||

| Machine size (mm) | 3000 x 1100×1780 | 5500 x 1100×1780 | 8500 x 1100×1780 |

| Machine weight (kg) | approx. 600 | approx. 1000 | approx. 1500 |

Options |

|||

| Closed cooling system | N | O | O |

| Supply system for protective gas | O | S | S |

| Photocell to position printed upper web | O | S | S |

| Posiform forming system | N | O | O |

| Figure cutting system | N | O | O |

| Roller shear cutting | N | O | O |

| Squeezing knife | O | O | O |

| Corrosion-resistant gripper chain | O | O | O |

| Automatic chain lubrication | O | O | O |

| Central lubrication system | O | O | O |

| Chain cleaning program | O | O | O |

| Extended loading area | N | O | O |

| Data printer | O | O | O |

| Labelling machine | N | O | O |

| Product dosing system | O | O | O |

| Possibility to work with oxygen more than 21% | O | O | O |

Machine

Machine

P1020668 JPG s

P1020668 JPG s

q1

q1

q2

q2

q4

q4

q5

q5

q6

q6

q7

q7

q9

q9

q10

q10

q11

q11

q12

q12

q14

q14

q16

q16

q17

q17

q166

q166

Riga Food 2010 004

Riga Food 2010 004

Riga Food 2010 005

Riga Food 2010 005

Riga Food 2010 008

Riga Food 2010 008

Riga Food 2010 009

Riga Food 2010 009

Riga Food 2010 016

Riga Food 2010 016

Riga Food 2010 017

Riga Food 2010 017

rollstock5

rollstock5

Scandivac packaging equipment

Scandivac packaging equipment

thermofirming packaging

thermofirming packaging

Vacuum packaging

Vacuum packaging

vacuum packaging products

vacuum packaging products

verp prod CIMG0267

verp prod CIMG0267

feta exo

feta exo

verp tz prod CIMG3324

verp tz prod CIMG3324

electronic display

electronic display